SINGAPORE, Sept. 9, 2020 /PRNewswire/ — With a shrinking working population and manpower shortage, many industries are hit hard, especially the logistics sector. Find out how Toshiba is addressing the needs of the manufacturing, distribution and logistics industries to mechanize and automate with advanced robotic solutions.

For the full multimedia release, click here: https://www.prnasia.com/mnr/toshiba_202009.shtml

Robots can estimate their own location using image recognition technology; the images they “see” are used to estimate their own location, thereby eliminating the need for rails or markers

The robot arm’s force sensor, which detects contact between boxes and walls, allows it to place boxes at the edge of a container, as a human being would.

Highly-intelligent robots and their place in the world

While industrial robots could operate within a certain defined parameter, they are not able to choose the most efficient method to do something in the face of a constantly-growing set of scenarios. An intelligent robot has to be created to perform irregular work — one that could “see” via image recognition technologies, “think” via motion planning technologies, and “act” via control technologies.

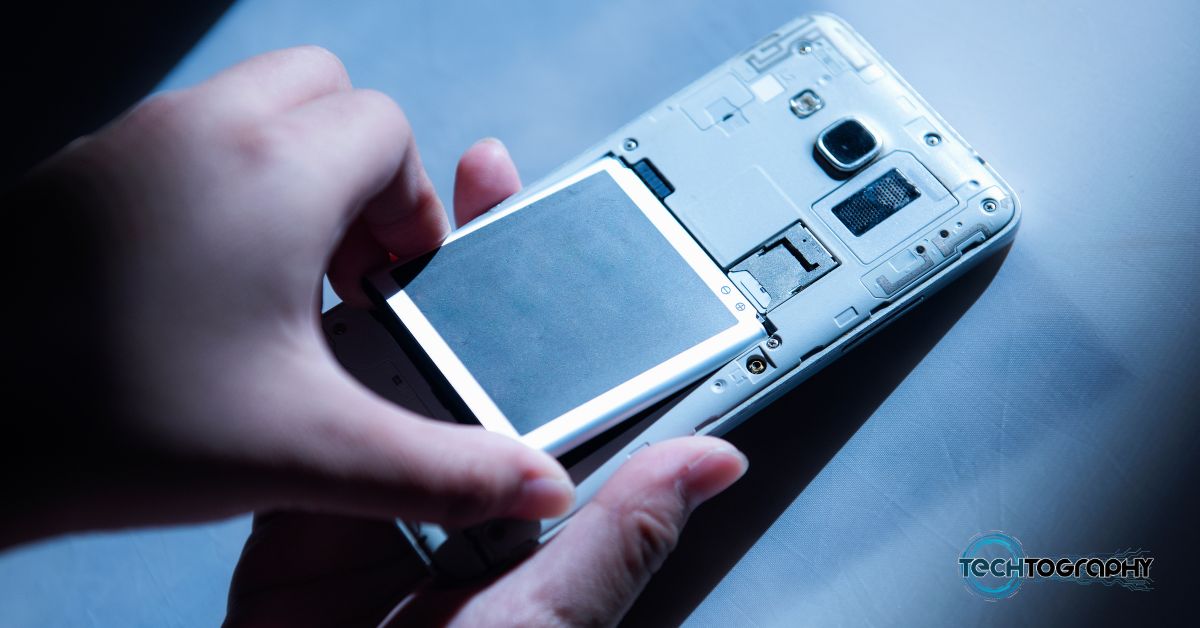

Image recognition technology is trying to do for robots what eyes do for human beings. It allows robots to compare their current position against a standard base position, allowing them to estimate their own location and move freely and accurately even in areas without rails or markers.

Motion planning technologies allow robots to create an ideal motion plan. They would need to take the information they acquired from the image recognition technology, run a series of simulations through computer-simulated models, and create what it would consider to be the best plan.

Once a motion plan has been created, the next step would be to “act” on it, using control technologies. In humans, that refers to the ability required to move in skillful ways. At Toshiba, a robot arm would need to do more than move exactly as prescribed in the simulation to be considered skillful.

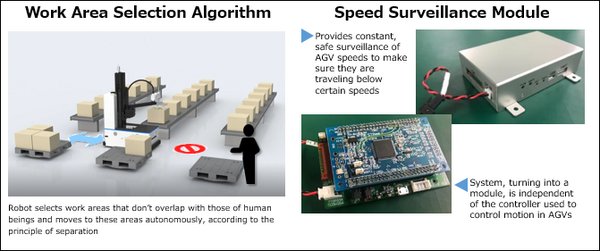

In the future, people will be working in closer proximity to robots than ever before. There is a major challenge to guarantee safety when it comes to this kind of human-to-robot replacement. Safety technologies that adhere to guidelines such as the ISO13849-1 can help keep human beings safe from robots.

Toshiba believes that all of the technologies that make up a robot should be based around the safety of human beings. As such, the company believes that the first priority should be removing the possibility of these kinds of incidents from the very first stage of development.

Photo – https://photos.prnasia.com/prnh/20200819/2889623-1-a?lang=0

Photo – https://photos.prnasia.com/prnh/20200819/2889623-1-b?lang=0

Photo – https://photos.prnasia.com/prnh/20200819/2889623-1-c?lang=0

Photo – https://photos.prnasia.com/prnh/20200819/2889623-1-d?lang=0