AI-powered Supply Chain capabilities to enable Chief Financial Officers, Chief Supply Chain Officers and other business leaders to quickly identify areas that most effectively accelerate the bottom line and drive sustained market advantage

PALO ALTO, Calif., Sept. 29, 2022 /PRNewswire/ — ThroughPut Inc., the Industrial AI Supply Chain pioneer, today announced the addition of key powerful financial capabilities to its supply chain software suite. The latest AI-powered software empowers businesses with a bird’s eye view of finances at the business unit and organizational level to identify those improvements in specific areas that can drive greater profitability and SKU-level contribution margins. Thus, organizations can eliminate the uncertainty of today’s market conditions and rapidly implement continuous improvements across their entire value chain, resulting in meaningful positive impacts to the bottom line quickly.

AI-powered Supply Chain capabilities to enable Chief Financial Officers, Chief Supply Chain Officers and other business leaders to quickly identify areas that most effectively accelerate the bottom line and drive sustained market advantage

In today’s increasingly dynamic markets, businesses need more than ever to do more with less – sell more, guarantee more value, grab more share of wallet, as well as market share – all with less effort, time, capital and costs. Failure to do this swiftly, smartly, and on a sustained basis leads to erosion of not only real and potential revenue, but also of market position, brand, and eventually customer loyalty.

"Every company generates reams of data. But your competitive advantage lies not in just visualizing that data, but rather your ability to drill down into the actionability hidden in every corner of your supply chain. Such AI-powered predictions lead to real business results for a healthy bottom-line," explained Seth Page, COO of ThroughPut Inc. "Such capabilities should be at the fingertips of every responsible CFO and executive today looking to achieve more in volatile markets. Investors, shareholders and stakeholders are increasingly demanding better and more predictable financial, operational and sustainability results, and innovative industry leaders are taking note. Ultimately the power lies in knowing how to manage and leverage market dynamics that many executives otherwise tend to think are out of our control. The good news is that it all boils down to Supply Chain Actionability – dynamic working capital and efficiency improvements at a micro level across the entire value chain. ThroughPut helps companies achieve this quickly by leveraging our Supply Chain AI on their existing disparate data sources".

Key Financial Capabilities

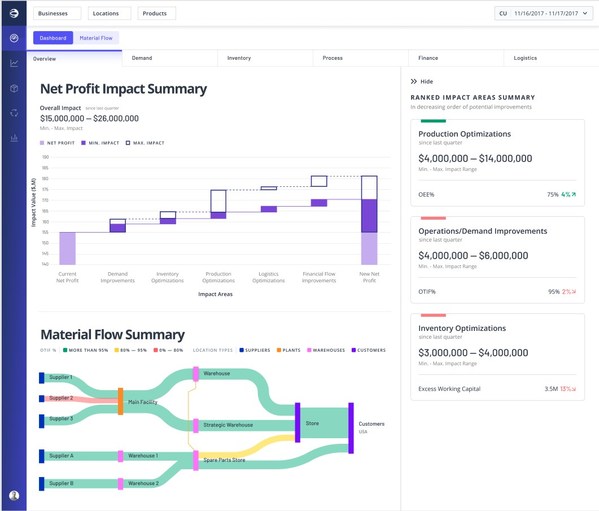

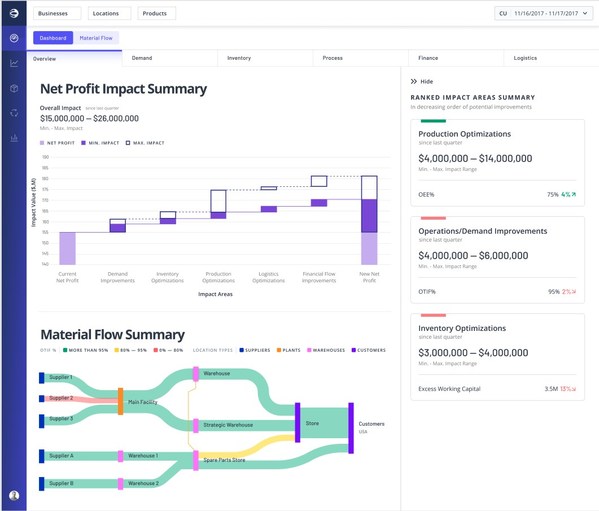

Dual Cascading Waterfalls: This graph compares the contributions of each area of impact on the net profit metric to assimilate all the interrelationships and dependencies that are an inherent part of the modern supply chain. It also:

- Summarizes the minimum and maximum range of impact across all business areas

- Shows the overall expected Net Profit impact at the Company or Business Unit level after addressing all evaluated impact areas

Financial Flow: By reducing costs across their supply chain processes and activities, businesses are able to minimize both their OPEX and CAPEX. In addition, cash flow conversion cycle analysis and a powerful overview of accounts payable, accounts receivable, and inventory turns enables businesses to:

- Quickly highlight high-impact areas that can improve free cash flows

- Leverage actionable recommendations to accelerate financial gains quickly

- Analyze recent change indicators to display the trajectory of business growth and how to best realize identified and predicted financial benefits

Listed below are key improvements for demand planning, inventory management, supply chain operations, and logistics management that the ThroughPut platform focuses on.

Demand Planning Improvements: With AI-driven demand planning, businesses gain the ability to translate the impact of their current order delivery rate (On-Time, In-Full – OTIF deliveries in terms of percentage) into lost throughput. This helps them to:

- Rapidly eliminate losses by identifying products that require operational improvements to unlock more sales (achievable recovery of lost sales), while freeing-up operational capacity

- Maximize available resources and increase revenue by determining the throughput improvement potential based on changing market conditions coupled with the recommended actions to achieve

Inventory Management Improvements: With top products utilizing excess working capital ranked by "Excess Working Capital" values, businesses can determine which products to stock-up more on, and which to cut-back on. This helps companies to:

- Maintain the optimal inventory levels that support operations, working capital spend requirements, and sales effort by ranking top-selling products that experience frequent stock-outs by at-risk value

- Identify working capital savings and minimize missed sales opportunities due to stock-outs by comparing current stock levels against historical stock levels to uncover excess inventory

Operational Improvements: Businesses can target balanced resource utilization rates while meeting existing and future demand with dynamically optimized inventory levels. They can also:

- Free-up potential capacity that can then be better utilized to cater to additional demand

- Minimize the risk of lost sales due to flagged production constraints

Logistics Improvements: Businesses can reduce unnecessary logistical movements (such as cross-shipments, shipments to external warehouses, and deliveries to distribution partners) due to incorrect resource allocation and overproduction by:

- Leveraging customized forecasts for demand, near-term OTIF potential, and product mix optimization to maximize profit margins

- Freely identifying and choosing logistics routes that best fit their goals and requirements following intelligent analysis of data on numerous potential network configuration options (including the optimal routes that incur the lowest costs, lowest CO2 emissions, greatest contribution margins, etc.)

ThroughPut is continuously working with leading CFOs, Chief Supply Chain Officers, businesses and other organizations across the globe to increase their supply chain visibility, actionability, resilience and business results quickly. Such capabilities enable industry leaders to minimize demand and supply variance, expensive inventory build-ups, and relentlessly rising labor, transportation, and material costs. As the supply chain optimization pioneer works toward its mission to level and stabilize the supply chain minefield for all innovative businesses, it promises continued improvements in end-to-end supply chain visibility and actionability, capital and operational asset optimization, effective inventory management, sustainability, and overall business results.

Additional Resources:

- For more information about ThroughPut, visit ThroughPut Resource Library

- Read the ThroughPut Blog and access latest ThroughPut Press Coverage

PR Contact

Tina Jacobs

About ThroughPut Inc

ThroughPut.ai is a Silicon Valley-based Supply Chain AI leader that puts Industrial material flow on Autopilot by leveraging existing Enterprise Data to achieve superior Business, Operations, Financial and Sustainability Results. ThroughPut’s AI-powered Supply Chain software predicts Demand, reorients Production Capacity, reassigns Warehouse Space, and reorders materials optimally, so businesses minimize overpromising and under-delivering, and maximize for their desired outcomes. ThroughPut improves material flow and free-cash-flow across the entire end-to-end value chain far faster than leading contemporary and legacy solutions. The founding team is led by seasoned serial entrepreneurs with real-world AI, Supply Chain, Manufacturing, Transportation and Operational experience, from the shop-floor to the top-floor, at leading Fortune 500 Industrial Companies & pioneering Enterprise Technology companies.

To learn more about ThroughPut Inc, visit www.throughput.ai