|

PERTH, Australia, June 30, 2021 /PRNewswire/ — Strategic Elements Ltd (ASX:SOR) has achieved a critical development milestone with its moisture powered battery successfully powering an IoT device equipped with both temperature and humidity sensors and onboard Bluetooth communication.

The advanced graphene oxide based battery ink technology enables extremely small, thin and light weight battery cells to be printed onto surfaces such as glass and flexible plastic. The battery cells are designed to be powered and self-charged solely by humidity in the air or from the skin. Graphene oxide and moisture from humidity in the air are a readily available, environmentally friendly source of energy compared to alternatives based on lithium and coin cells.

Bluetooth Communication and Sensor Demonstration

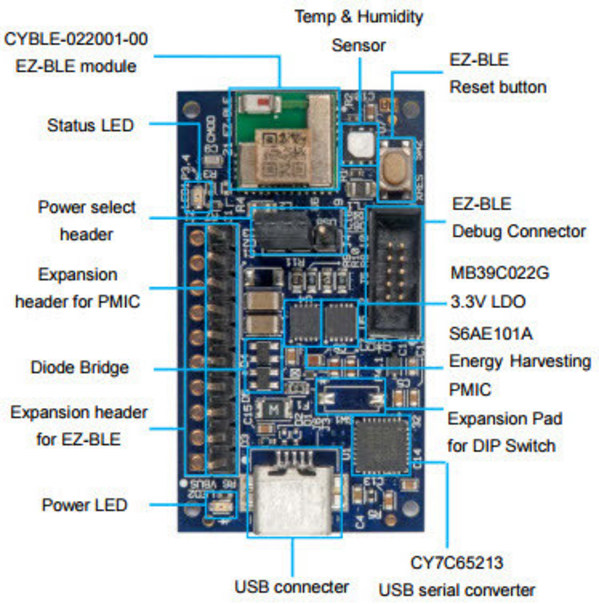

A demonstrator battery harvested energy from moisture in the air and converted this to power a Cypress Semiconductor IoT sensor kit with fully integrated:

- Electronic control board

- Bluetooth Low Energy (BLE) communication module

- Temperature sensor

- Humidity sensor

Battery ink cells successfully enabled real time temperature and humidity data to be captured and transmitted wirelessly to a laptop via sensors and a BLE communication module over the 5 hour testing period with a sampling rate of 7 seconds.

Significantly, for the first time battery ink cells were integrated with a commercial supercapacitor. This is a significant advancement as higher performance applications require a supercapacitor/battery for greater energy storage.

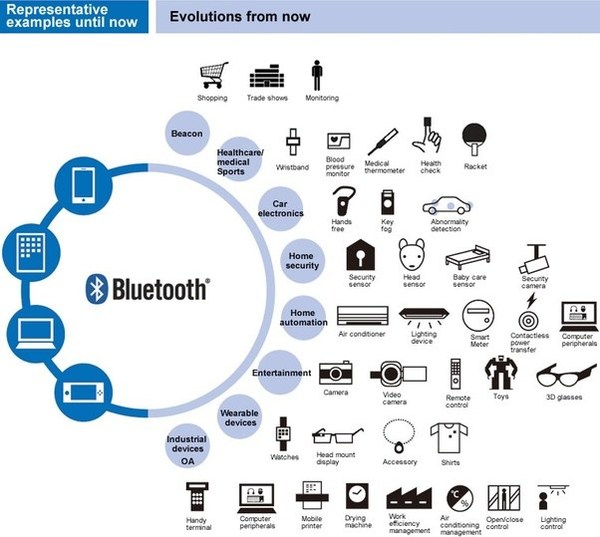

The Cypress Semiconductor IoT sensor kit is a development platform for IoT devices with BLE wireless connectivity. The fully integrated module is designed to demonstrate development potential of various components (including power sources) for a wide range of IoT devices. This includes, for example, smart buildings and homes where temperature and humidity are core sensors in a large multi-billion dollar market. BLE wireless connectivity is also set to expand with increasing use of building energy management systems to collect data via a network of wireless sensors.

Screen Printing Development

The battery ink is being designed to produce a battery pack with a large number of miniature battery cells. Scaling down cell size means more batteries can be assembled in the same area leading to increased power output. This is similar to computer chips where greater performance has been achieved by scaling down memory cell size and increasing density.

Global electronics companies have adopted traditional screen printing methods to enable miniature electronic components (down to micrometre size) to be printed onto sheets of plastic.

– Scaling down cell size through screen printing can potentially significantly increase power output from the same area.

– Battery ink cells fabricated by the Company to date are approximately 0.25cm2 in size. Screen printing equipment at UNSW has technical capability to print components hundreds of times smaller than the current battery ink cell size.

Significant materials engineering to customise the battery ink for screen printing has been conducted. Taking COVID restrictions into account, the Company will aim to finalise development and testing of a prototype battery ink formulated for screen printing over the next few weeks.

Milliamp Battery Pack

The Company is intending to develop a prototype battery pack producing over a milliamp of electrical current mid Q3 2021.This will be recognised as a significant milestone as it dramatically expands the range of electronic devices the battery can potentially power. If the screen printing battery ink, scaling and milliamp work is successful the Company will proceed to investigate pathways to generating a significantly larger amount of energy than has been contemplated to date.

Highly Skilled Team and Collaboration

Development is under an Australian Research Council part-funded collaboration between the Company and the University of New South Wales (announced 30/7/20). The group at UNSW have developed deep experience in electronic inks, energy harvesting and storage over the past 10 years and are applying that in development of the Battery Ink technology. UNSW School of Materials Science and Engineering is ranked #1 in Australia for material science and have a number of partnerships with leading companies such as Boral, Hitachi Chemical, One Steel and many more. UNSW has world-class infrastructure and equipment geared towards advanced materials engineering and fabrication.

About the Company

The Australian Federal Government has registered Strategic Elements as a Pooled Development Fund with a mandate to back Australian innovation. The Company operates as a venture builder where it generates high risk-high reward ventures and projects from combining teams of leading scientists or innovators. Investors in SOR potentially pay no tax on capital gains from selling their SOR shares as the Company operates under the Pooled Development program setup to encourage investment into innovation. Through its 100% owned subsidiaries the Company is:

- Collaborating with giant US Fortune 100 Company Honeywell to build autonomous robotic security vehicles for the correctional justice sector.

- Working with CSIRO and has licensed world leading CSIRO technology that enables robots to work together in teams.

- Developing printable electronic inks for batteries, neuromorphic computing and RRAM memory applications with the University of New South Wales.

More information on the Pooled Development Program is available on the Company’s website. The Company is listed on the ASX under the code "SOR".

www.strategicelements.com.au

This announcement was authorised for release by Strategic Elements’ Board of Directors.

Related Links :